There are many options for the type of glass used in window and door products. Some things to consider when determining glass type are:

Annealing of glass is the process of slowly cooling hot glass objects after they have been formed to relieve residual internal stresses introduced during manufacture. Annealed glass is standard duty float glass that provides excellent clarity. Annealing of glass is critical to its durability so it does not crack or shatter when subjected to relatively small temperature changes or to mechanical shock or stress, an important feature in the manufacture of windows.

Heating glass to a high temperature of 454–482°C achieves the stress-relief point, or Annealing point, of the glass. In this form glass is in a liquid state and is floated on a pool of molten tin - why it is referenced as “float glass”.

After slowly cooling the glass so as not to create any tension, it's cut into large sheets and shipped off to other manufacturers to be tempered, heat strengthened, or cut and put to use.

LAMINATED GLASS

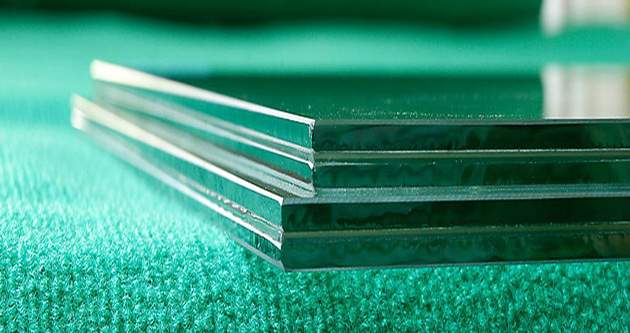

Laminated glass is multiple layers of tempered glass with a vinyl interlayer sandwiched between the layers. When laminated glass is broken, the vinyl interlayer remains in the frame with the glass fragments adhering to the interlayer providing homeowners with safety and security. Laminated glass cannot be cut from only one side, rendering glass cutters useless, and making it a best choice for security application.

When laminated glass is added to an Insulated Glass unit, it increases the OITC (Outdoor/Indoor Transmission Class) of a window and improves its sound isolation performance.

Offering twice the fade protection of ordinary glass, laminated glass can block over 95% of the sun's UV energy while still allowing most of the visible light through - a consideration to avoid the fading of fabric, furniture, and other home materials.

For impact resistance windows, laminated glass is also crafted to offer a high level of impact resistance and to remain integral in the window envelope even after glass breakage, offering security to homeowners in impact zones.

- The CLIMATE the product will be used in

- What KIND OF PROJECT it will be used in (residential, commercial and the codes and regulations around each)

- The ENERGY EFFICIENCY GOALS of the customer.

Annealing of glass is the process of slowly cooling hot glass objects after they have been formed to relieve residual internal stresses introduced during manufacture. Annealed glass is standard duty float glass that provides excellent clarity. Annealing of glass is critical to its durability so it does not crack or shatter when subjected to relatively small temperature changes or to mechanical shock or stress, an important feature in the manufacture of windows.

Heating glass to a high temperature of 454–482°C achieves the stress-relief point, or Annealing point, of the glass. In this form glass is in a liquid state and is floated on a pool of molten tin - why it is referenced as “float glass”.

After slowly cooling the glass so as not to create any tension, it's cut into large sheets and shipped off to other manufacturers to be tempered, heat strengthened, or cut and put to use.

LAMINATED GLASS

Laminated glass is multiple layers of tempered glass with a vinyl interlayer sandwiched between the layers. When laminated glass is broken, the vinyl interlayer remains in the frame with the glass fragments adhering to the interlayer providing homeowners with safety and security. Laminated glass cannot be cut from only one side, rendering glass cutters useless, and making it a best choice for security application.

When laminated glass is added to an Insulated Glass unit, it increases the OITC (Outdoor/Indoor Transmission Class) of a window and improves its sound isolation performance.

Offering twice the fade protection of ordinary glass, laminated glass can block over 95% of the sun's UV energy while still allowing most of the visible light through - a consideration to avoid the fading of fabric, furniture, and other home materials.

For impact resistance windows, laminated glass is also crafted to offer a high level of impact resistance and to remain integral in the window envelope even after glass breakage, offering security to homeowners in impact zones.

TEMPERED GLASS

Tempered glass is the most common safety glass used in windows; it is often required for larger window units, in bathrooms and bedrooms, in commercial spaces, and is the standard glazing type for door products.

Tempered glass is a type of safety glass processed by controlled thermal or chemical treatments in order to increase its strength. Tempering puts the outer surfaces into compression and the interior surfaces into tension. Such stresses cause the glass, when broken, to crumble into small granular chunks instead of splintering. The granular chunks are less likely to cause injury.

Tempered glass is physically and thermally stronger than annealed glass.

The greater contraction of the inner layer during manufacturing induces compressive stresses in the surface of the glass balanced by tensile stresses. It is this compressive stress that gives the tempered glass increased strength, which is two to four times stronger than a piece of annealed glass.

Any cutting or grinding of tempered glass must be done prior to tempering, as cutting, grinding, and sharp impacts after tempering will cause the glass to fracture.

Tempered glass is the most common safety glass used in windows; it is often required for larger window units, in bathrooms and bedrooms, in commercial spaces, and is the standard glazing type for door products.

Tempered glass is a type of safety glass processed by controlled thermal or chemical treatments in order to increase its strength. Tempering puts the outer surfaces into compression and the interior surfaces into tension. Such stresses cause the glass, when broken, to crumble into small granular chunks instead of splintering. The granular chunks are less likely to cause injury.

Tempered glass is physically and thermally stronger than annealed glass.

The greater contraction of the inner layer during manufacturing induces compressive stresses in the surface of the glass balanced by tensile stresses. It is this compressive stress that gives the tempered glass increased strength, which is two to four times stronger than a piece of annealed glass.

Any cutting or grinding of tempered glass must be done prior to tempering, as cutting, grinding, and sharp impacts after tempering will cause the glass to fracture.

RSS Feed

RSS Feed